Mild metal and solid iron are two common types of metals. Both are used in many industries. They are robust; however, their traits are specific. Knowing the variations enables choosing the right steel for the job.

In this article, we will explain Mild Steel vs Cast Iron in simple words. We may also show why some businesses select providers of excessively satisfactory carbon metallic bar for mild steel.

What Is Mild Steel?

Mild steel is a kind of carbon steel. The quantity of carbon in it is much less. Generally, the amount of carbon is zero.05% to zero.25%.

Properties of mild metal:

soft and flexible

can be effortlessly fashioned

Can be effortlessly welded and cut

Rusts extra slowly than forged iron

robust, however, no longer too tough

Mild metal is widely used within the creation, automotive and device industries. It is simple to bend, weld and device.

What Is Cast Iron?

Cast iron is also a sort of carbon steel; it has a higher carbon content. Generally, the carbon content is 2% to 4%.

Properties of solid iron:

hard and brittle

tough to bend or shape

cannot be welded effortlessly

excellent at compression

Rusts more quickly than mild steel

Cast iron is regularly used for engine blocks, pipes, cookware and heavy machinery. Also, it is powerful enough to hold the weight, and however can be wrecked if hit too hard.

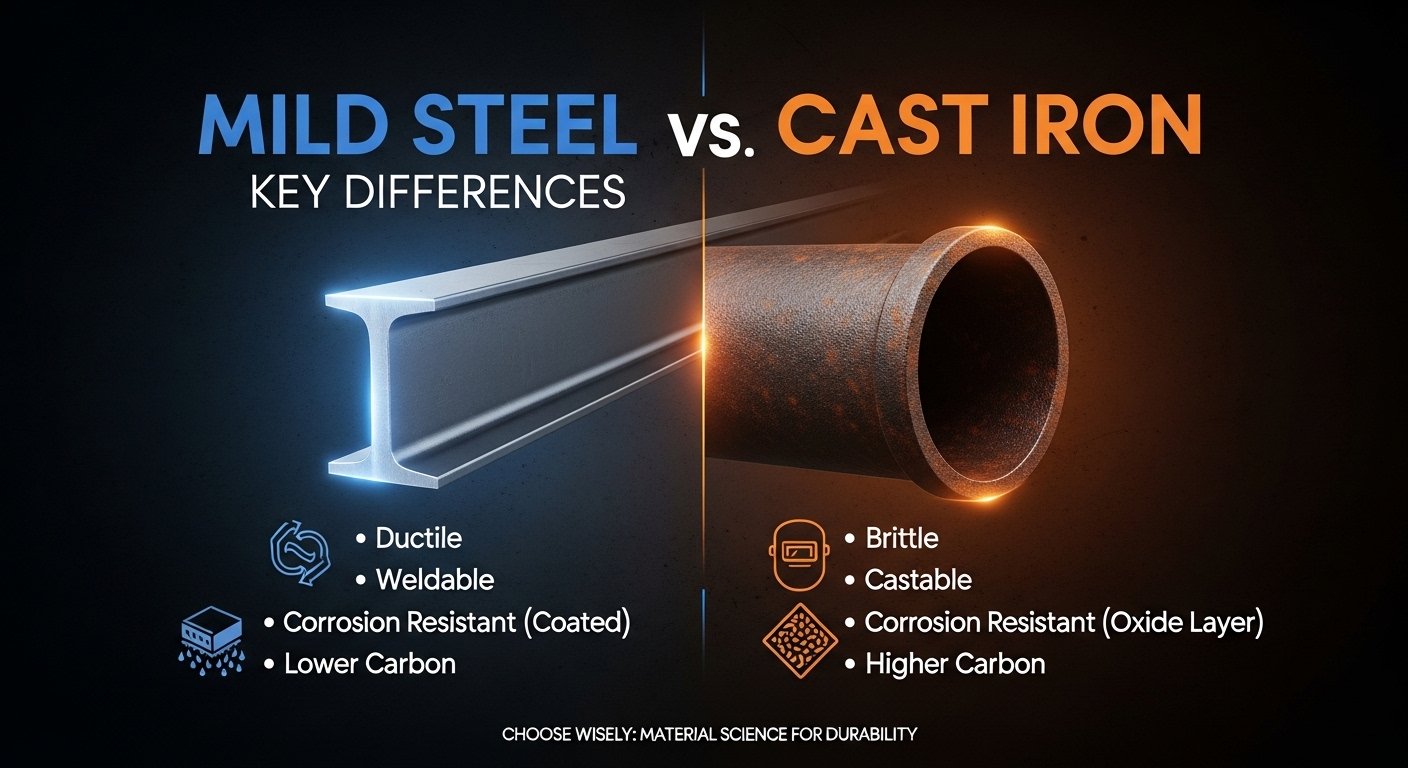

Mild Steel vs Cast Iron: Key Differences

Here are the principal variations between moderate steel and solid iron.

1. Carbon content

Mild steel: low carbon (zero.05%–zero. 25%)

Cast iron: excessive carbon (2%–four %)

The much lower carbon in mild steel makes it softer and less complicated to form. also the excessive carbon in forged iron makes it hard and brittle.

2. Strength and toughness

Alloy: like strong, but not very hard. Can bend without breaking.

Cast iron: Very hard, however brittle. It can cause damage if hit hard.

Lighter metals are better for additives that require bending. Cast iron is extra appropriate for heavy loads and compression.

3. Flexibility and versatility

Light steel: Very bendy and malleable. Can be stretched or bent.

Cast iron: Very brittle. Cannot bend or stretch.

This makes it less complicated to work with the medium-sized metallic in flora and machines.

4. Welding and machining

Mild metal: Easy to weld, reduce and gadget.

Cast iron: Difficult to weld and machine.

Companies decide on stainless steel for components that require welding or reducing. This is why it is important to deliver high-quality carbon steel bars to industries that use moderate metallic.

5. Corrosion resistance

Mild metal: Rusts slowly; however may be coated with paint or zinc.

Cast iron: Rusts quickly when uncovered to water or air.

If the product might be exposed to rain or moisture, mild steel is normally favoured.

6. Weight

Mild metallic: Lighter than cast iron.

Cast iron: Heavy due to high carbon content.

Lightweight materials are easy to transport and use in machines. Heavier forged iron is higher for stability in large equipment.

7. Cost

Mild metal: Cheap and easy to make.

Cast iron: Slightly steeply priced because of processing.

For huge-scale production or mass manufacturing, moderate metallic is desired due to fee and simplicity of use.

8. Applications

Mild steel applications:

- Construction beams

- Car bodies and frames

- Pipes and tubes

- Machinery parts

Cast iron applications:

- Engine blocks

- Pipes and water tanks

- Cookware (like pans)

- Heavy machinery bases

Why Choose Mild Steel?

Mild steel is popular because it is easy to work with. also It can be cut, welded, and shaped. It is also cheaper than cast iron.

Many industries buy mild steel from a High-Quality Carbon Steel Bars Supplier. And they get steel in bars, sheets, or rods. Mild steel can be coated to prevent rust.

Why Choose Cast Iron?

Cast iron is very hard and strong. also it can hold heavy loads. It is often used where strength and compression are important.

However, cast iron is brittle. If it is hit or dropped, it can break. It is also hard to weld or shape.

Summary Table: Mild Steel vs Cast Iron

Property Mild Steel Cast Iron

Carbon content Low (0.05%–0.25%) High (2%–4%)

Strength Strong, flexible Very hard, brittle

Welding Easy Difficult

Rust Slow Fast

Weight Light Heavy

Cost Cheaper Expensive

Conclusion

Mild steel and forged iron are each vital metals. They have unique makes use of.

Mild metal is gentle, malleable, easy to weld and cheap. It is utilised in production, cars and equipment.

Cast iron is difficult, brittle and sturdy in compression. It is used in engine blocks, heavy machinery and cooking vessels.

Choosing the right steel depends on your assignment. If you need to show, weld or reduce, mild metallic is better. If you want electricity and stability, cast iron is higher.

For industries that use steel, a supplier of high first-rate carbon steel bars may be very essential. They provide sturdy, reliable and user-friendly metal.

By knowing the distinction among slight metal vs cast iron, groups can select the proper cloth. This guarantees safety, energy and long-lasting merchandise.